MotionTrex shows you what’s really happening in logistics

✓ Real-time location of goods, containers, and employees

✓ Alerts for deviations and rule violations

✓ Historical data and trends

✓ Evaluation of changes based on Lean principles

✓ Performance comparison between teams

✓ Automated detection of inefficiencies

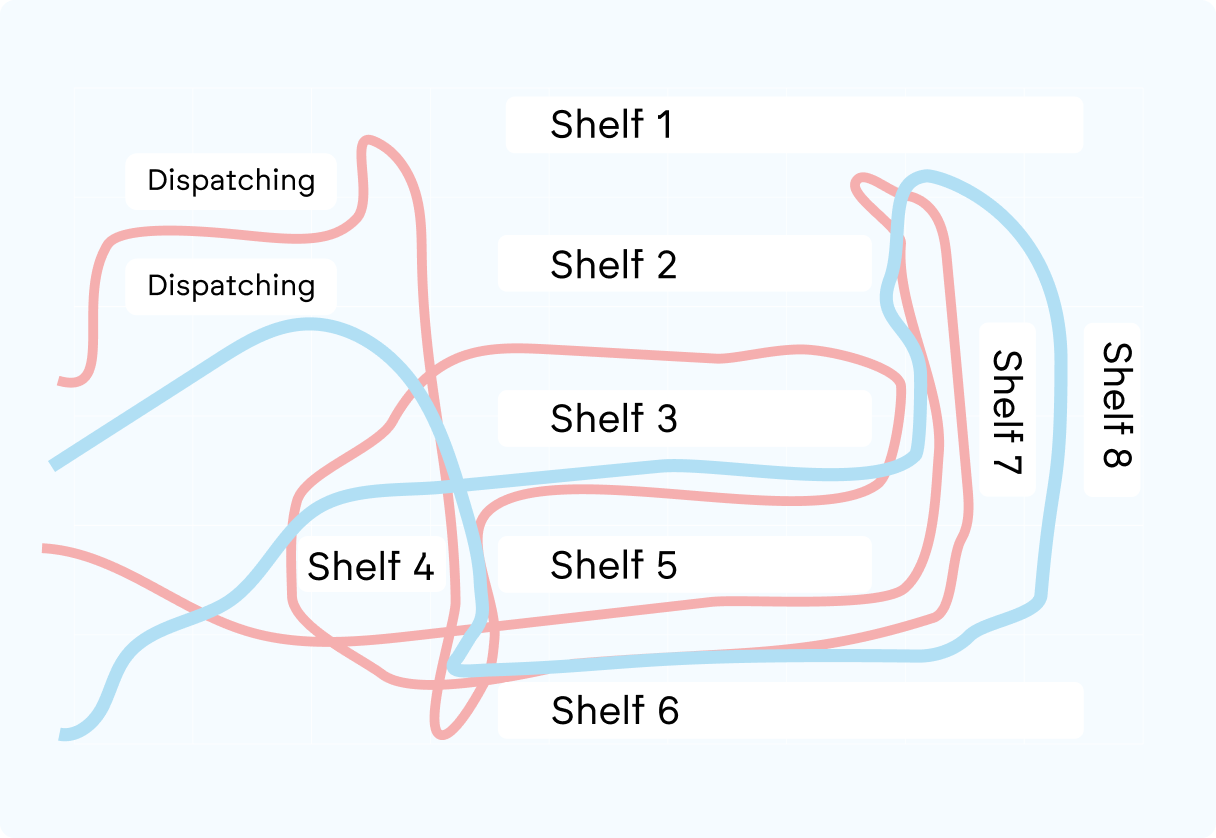

Spaghetti diagram

MotionTrex uses a Spaghetti diagram to show how goods, people and equipment move across your operations. You can instantly spot inefficient routes, reduce unnecessary travel distances and increase productivity.

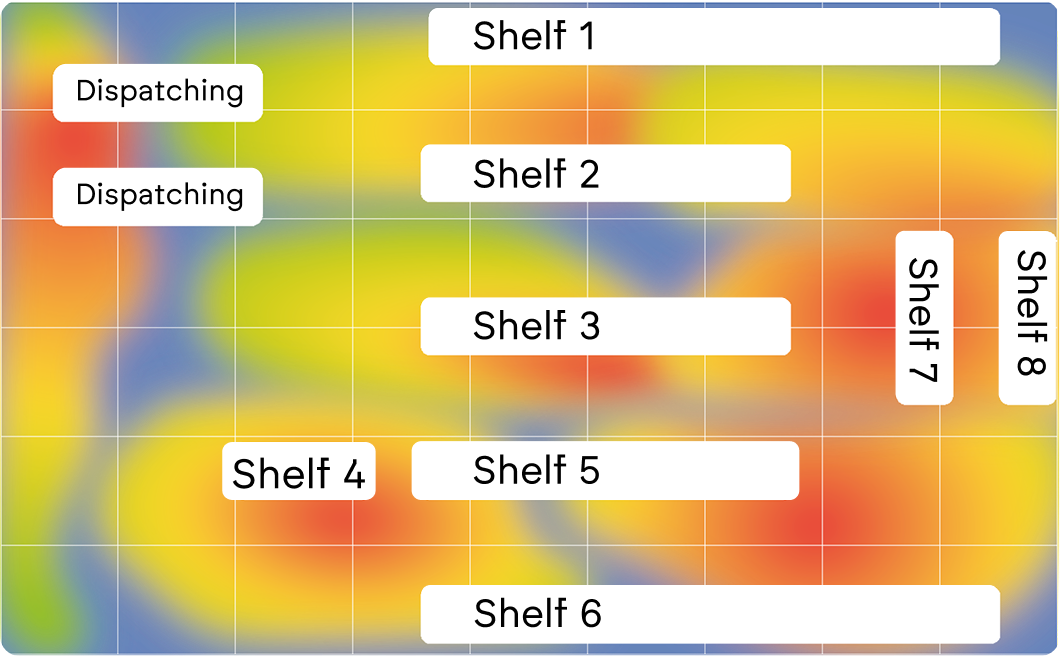

Heat map

MotionTrex uses heat maps to reveal the busiest areas of your operation. You can quickly see where overloads, unused capacity or inefficient movement occur – allowing you to take immediate action.

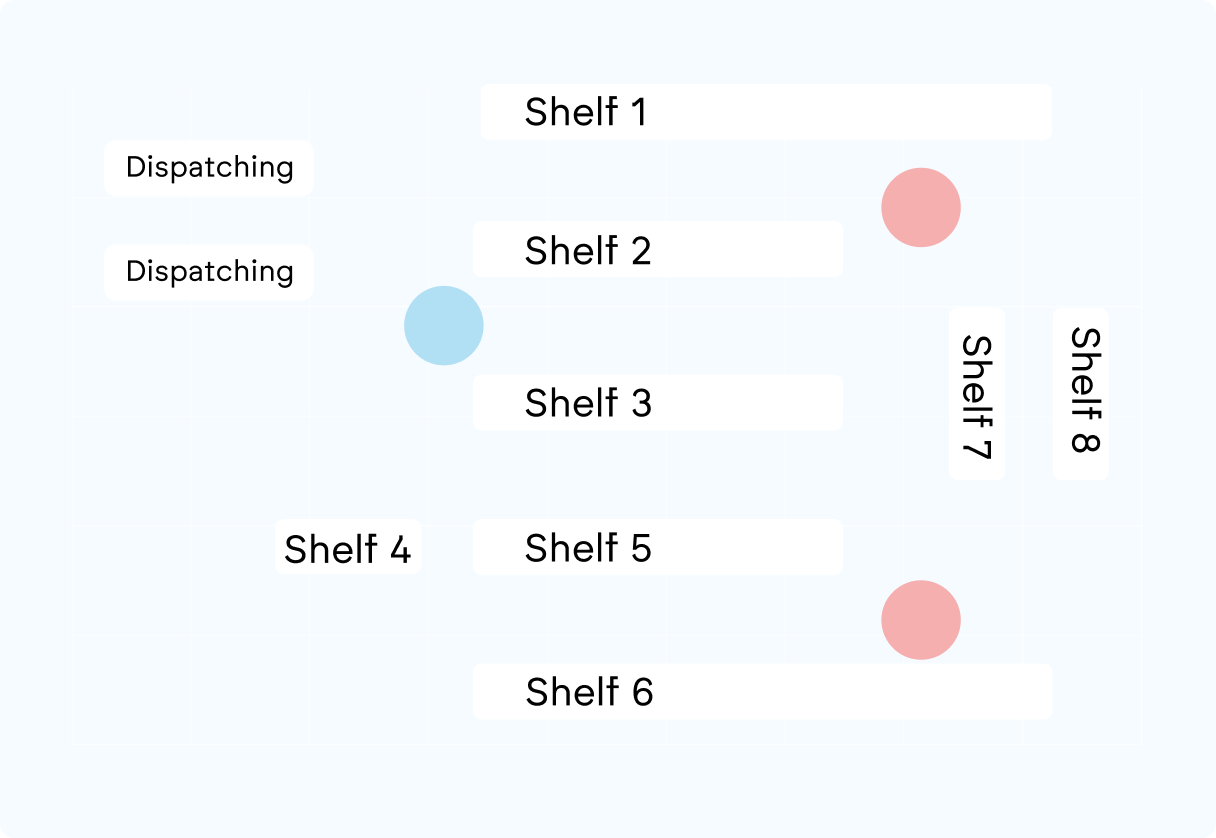

Real-time movement

MotionTrex lets you track the movement of goods, people and equipment in real time. You always know what’s happening in your operation and can respond quickly to any changes or problems.

Implementation

How do you deploy MotionTrex?

When you want insights into movement within your warehouse, you don’t need months of preparation. With MotionTrex, you can get started right away – simply, without disrupting operations and with fast results.

1. Analysis of existing data sources

We review and integrate the available data from systems such as RFID, WMS, or entry cards. We make sure that all available data is fully utilized – regardless of its origin.

Example: By combining data from RFID readers and handling equipment, you can improve the accuracy of information on material flows and workload.

2. Applying MotionTrex models

Based on the available data, we create analytical models that identify weak points and propose the first steps toward improvement. The system also constantly learns from operational behavior, enabling ongoing optimization.

Example: The models may show that certain warehouse zones are systematically overloaded while others remain underutilized.

3. Expanding the motion-tracking system

We gradually expand the coverage of the RTLS (Real-Time Location System), monitor ROI, and implement advanced features – such as alerts, predictions, or heat map visualizations.

All steps are tailored to your needs.

Example: The system begins to detect delays in the packing zone that previously went unnoticed and notifies you in real time.

Our partners:

“We analyze data on the movement of goods, people and equipment to increase efficiency, reduce costs and ensure compliance.”

Michal Kašpárek, Technology expert

Quick links

Kontakt

MotionTrex spol. s r.o.

Jabloňová 2929/30

Praha 10 110 00

IČ: 199 94 460

Kontakt: Štěpán Malý

Tel.: +420 773 547 119

E-mail: stepan.maly@motiontrex.com

Tento projekt byl realizován za finanční podpory programu Technologická inkubace.

This project was carried out with financial support from the Technology Incubation Program.